How to Choose the Right Cable Tray for Your Electrical Installation Needs

In today's rapidly evolving electrical infrastructure landscape, the selection of the right cable tray is crucial for ensuring safety, efficiency, and longevity in installations. According to a recent market research report by MarketsandMarkets, the global cable tray market is projected to grow from $2.8 billion in 2021 to $4.3 billion by 2026, driven by the increasing demand for organized and safe cable management in industrial, commercial, and residential sectors. As industries prioritize operational reliability and maintenance ease, the importance of choosing the appropriate cable tray cannot be overstated. Proper selection not only impacts the performance and durability of electrical systems but also plays a vital role in minimizing hazards. This blog will provide insights into key factors to consider when choosing the right cable tray for your specific electrical installation needs.

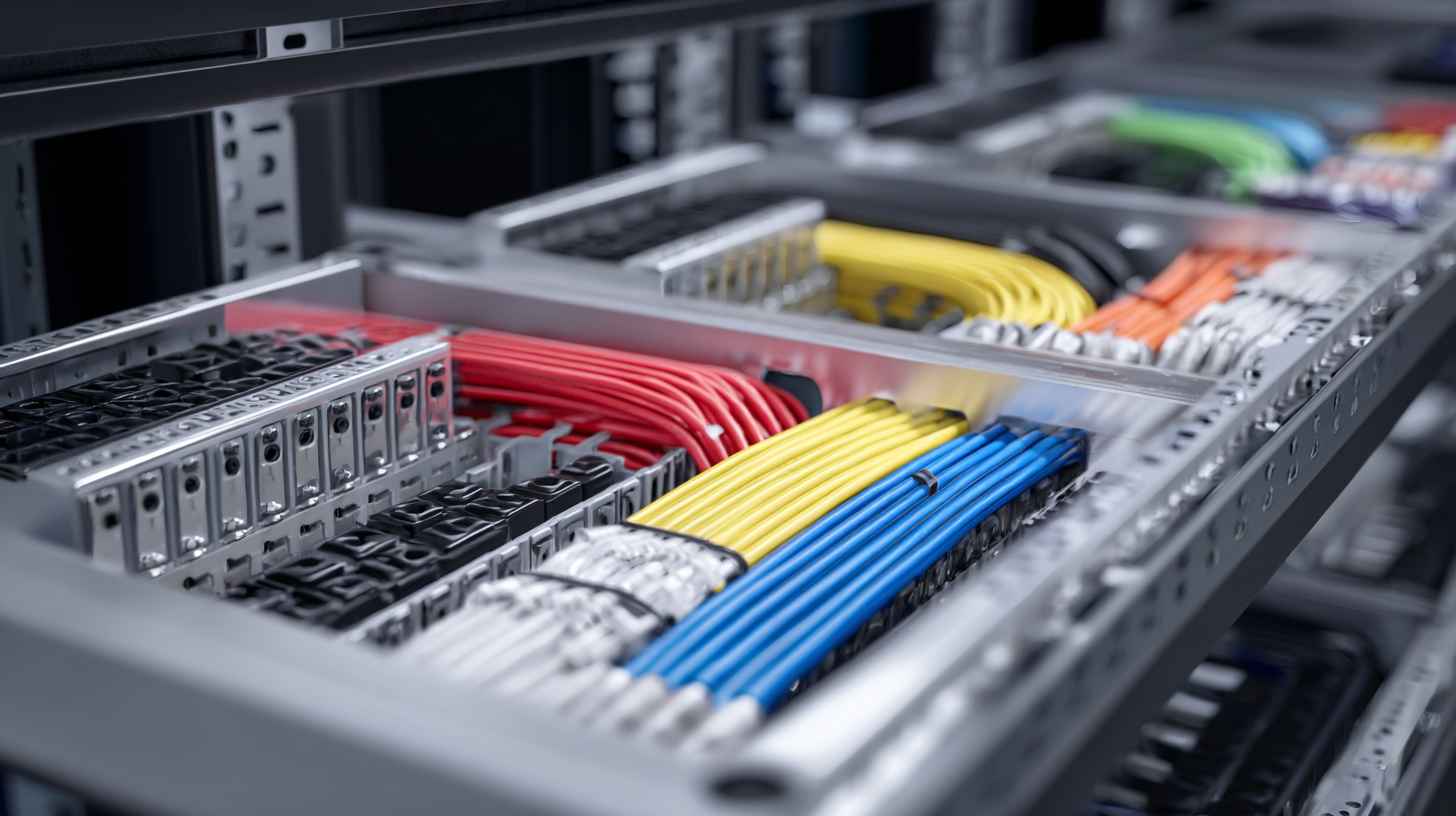

Understanding the Different Types of Cable Trays and Their Applications

When selecting the right cable tray for your electrical installation needs, it's essential to understand the various types available and their specific applications. Cable trays are an integral part of electrical infrastructure, offering support for cables while promoting organization and safety. The most common types include ladder-type trays, solid bottom trays, and perforated trays, each designed for different uses. Ladder trays, with their open design, are ideal for larger cables and areas requiring ventilation, while solid bottom trays provide protection for the cables in environments where dust or moisture is a concern.

The growth in the cable tray market highlights the increasing demand for efficient and reliable cable management solutions. With projections indicating the cable tray market could expand significantly from $5.66 billion in 2024 to $9.09 billion by 2032, it reflects a broader trend toward improved electrical infrastructure across industries. Understanding which type of cable tray fits your particular setup is critical for ensuring the longevity and safety of your electrical systems. As projects evolve, so too will the technologies and materials that enhance the performance of these essential components.

How to Choose the Right Cable Tray for Your Electrical Installation Needs

| Cable Tray Type | Material | Load Capacity | Typical Applications |

|---|---|---|---|

| Ladder Tray | Steel | Up to 5000 lbs | Power distribution, telecommunications |

| Solid Bottom Tray | Aluminum | Up to 3000 lbs | Data centers, industrial plants |

| Perforated Tray | Steel | Up to 4000 lbs | Commercial buildings, light duty applications |

| Cable Tray with Covers | Fiberglass | Up to 2000 lbs | Outdoor installations, hazardous environments |

Key Factors to Consider When Selecting a Cable Tray

When selecting a cable tray for your electrical installation, several key factors should be considered to ensure optimal performance and compliance with industry standards. Firstly, the material of the cable tray is crucial; options such as steel, aluminum, or fiberglass each have their own benefits regarding durability, strength, and resistance to corrosion. For environments subjected to moisture or harsh chemicals, a protective coating or non-metallic solutions might be preferred to extend lifespan and minimize maintenance.

In addition to material, the tray’s configuration is essential. Choose the right size and design that accommodates the volume and types of cables you plan to install. Considerations such as load capacity, width, and height are paramount to prevent overcrowding and potential damage to cables. Moreover, assessing the installation environment (indoor vs. outdoor, temperature fluctuations, etc.) will guide you toward the appropriate tray design that ensures safety and efficiency in your electrical systems. Taking these factors into account will help you make an informed decision, ultimately leading to a more reliable and effective electrical installation.

Material Choices for Cable Trays: Pros and Cons

When selecting cable trays for electrical installations, material choice plays a crucial role in ensuring longevity and performance. The two most common materials for cable trays are steel and aluminum.

Steel, often galvanized, offers exceptional strength and is ideal for heavy-duty applications. According to a report by the National Electrical Manufacturers Association (NEMA), steel cable trays can withstand more than 2,000 pounds of load, making them suitable for industrial environments where cables bear significant weight. However, steel is prone to corrosion, which can be mitigated through proper coatings and maintenance, but this adds to the overall cost.

On the other hand, aluminum cable trays are becoming increasingly popular due to their lightweight nature and resistance to corrosion. The International Electrotechnical Commission (IEC) notes that aluminum trays can last up to 25 years in hostile environments without significant degradation. Although aluminum trays typically have a lower load-bearing capacity compared to steel, advancements in design have led to high-strength aluminum options that can competently support various installations. However, the initial cost of aluminum can be higher, which is an important consideration for budget-conscious projects.

By weighing these material options, you can make informed decisions tailored to your specific electrical installation needs.

Installation Requirements for Various Cable Tray Types

When choosing the right cable tray for your electrical installation needs, it's essential to understand the installation requirements for various types of cable trays. The cable management market, projected to reach $9.2 billion globally by 2032, indicates a growing demand for effective solutions like cable trays, which are classified into several types, including ladder, solid bottom, and trough configurations. Each type has distinct installation considerations, such as load capacity, environmental factors, and the type of cabling being used.

For instance, ladder-type cable trays are typically preferred for heavy-duty applications due to their strength and ventilation capabilities. In contrast, solid-bottom trays offer additional protection from environmental hazards and are ideal for smaller, less invasive installations. With anticipation of a CAGR of 6.12%, understanding the nuances of these installation requirements is critical to ensure safety and efficiency in your electrical systems, making informed choices based on material properties and application suitability vital for successful implementation.

Choosing the Right Cable Tray Types for Electrical Installations

Maintenance Tips for Optimizing Cable Tray Performance

When it comes to optimizing cable tray performance, regular maintenance is essential to prolonging its lifespan and ensuring efficiency in electrical installations. According to a report by the International Society of Automation, improperly maintained cable trays can lead to up to a 30% decrease in operational efficiency due to issues such as corrosion and material degradation. Regular inspections should focus on checking for signs of wear, ensuring proper support and alignment, and verifying that all fixtures are securely fastened to prevent movement and vibration damage.

In addition to periodic inspections, maintaining a clean cable tray environment is vital. Accumulation of dust, debris, and moisture can adversely affect the performance of the cables housed within. A study by the National Electrical Manufacturers Association indicates that a clean cable pathway can reduce maintenance costs by up to 25%, as it minimizes the risk of electrical faults and overheating. Implementing a cleaning schedule and utilizing appropriate cleaning materials can significantly enhance the operational longevity of cable trays, ensuring they perform to their maximum potential and contribute efficiently to your electrical systems.

Related Posts

-

How to Choose the Best Ladder Cable Tray: A Comprehensive Step-by-Step Guide

-

Uncompromising Quality in Best Tray Cables Made in China for the Global Market

-

Setting the Benchmark: Industry Standards for the Best Basket Tray Production

-

Exploring Alternative Solutions to the Best Wire Basket Cable Tray

-

Solutions for Optimal Cable Management with Best Cable Basket

-

How to Choose the Best Wire Cable Tray for Your Industrial Needs