How to Choose the Right Cable Hangers for Your Project Needs

Choosing the right cable hangers for your project is crucial for ensuring a neat, organized, and safe electrical setup. Whether you are working on a large-scale commercial installation or a simple home improvement project, the selection of appropriate cable hangers can significantly impact the overall efficiency and longevity of your wiring systems.

With various materials, designs, and load capacities available in the market, it can be overwhelming to determine which cable hangers will best suit your specific needs. This guide will walk you through key considerations such as the type of cables being used, environmental factors, and installation methods. By understanding these essential elements, you will be better equipped to make informed decisions that enhance the functionality and safety of your electrical projects.

Understanding Different Types of Cable Hangers Available in the Market

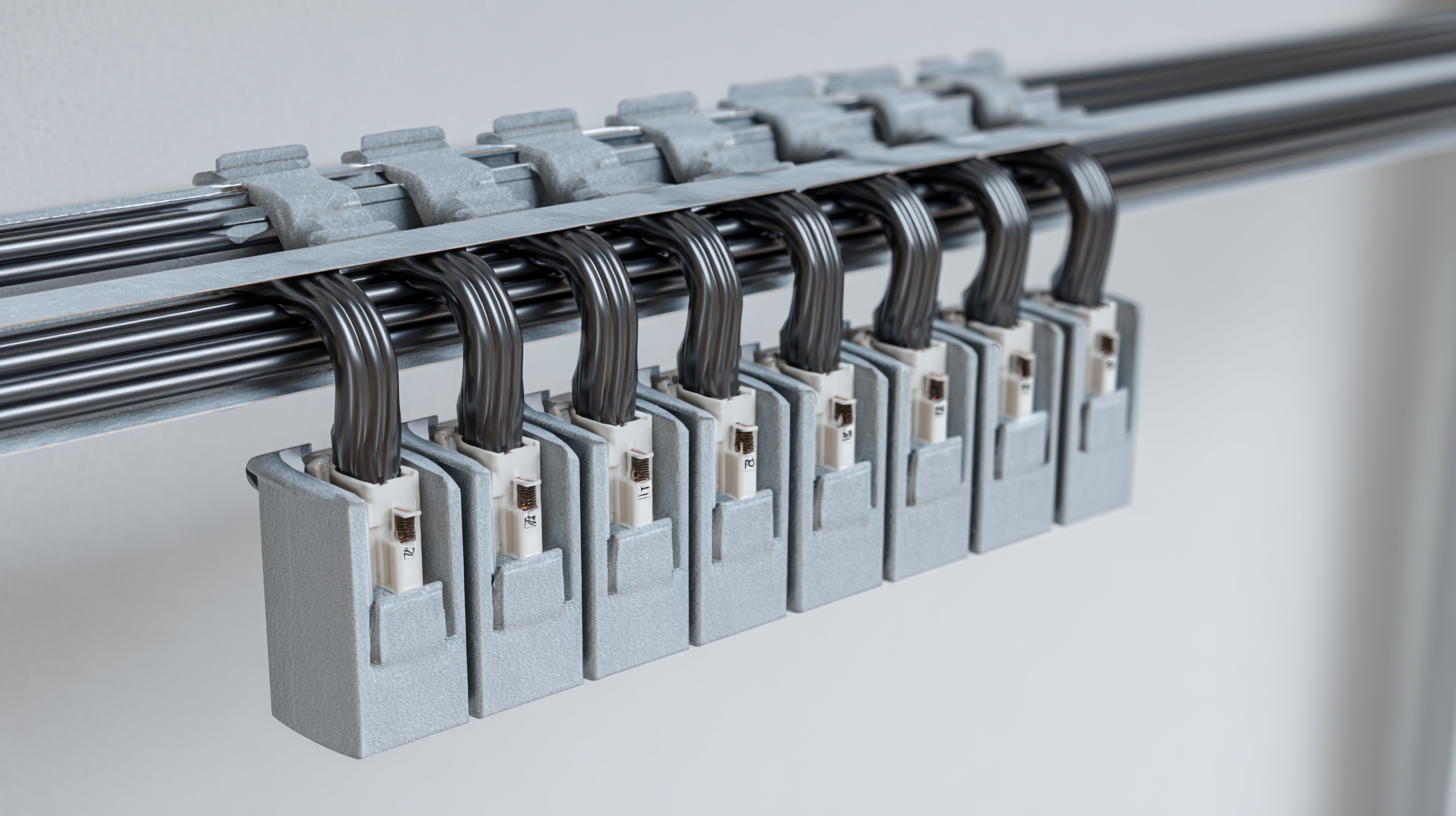

When selecting cable hangers for your project, it's essential to understand the various types available in the market, as each type serves a specific purpose based on the application. A common choice is the standard cable tie mount, which is designed for organizing and securing loose cables against walls or surfaces. These mounts come in various materials, including plastic and metal, allowing for flexibility depending on the cable weight and environmental factors.

For projects requiring heavier loads, adjustable cable clamps are ideal. These clamps provide a secure hold and can accommodate different cable sizes. They are typically used in industrial settings where durability is paramount. Additionally, there are snap-on cable hangers, which are favored for their ease of installation and ability to hold multiple cables without slipping. Understanding the specific requirements of your project, such as load capacity and installation environment, will help you choose the most effective cable hangers to ensure a neat and organized setup.

How to Choose the Right Cable Hangers for Your Project Needs

Factors to Consider When Selecting Cable Hangers for Specific Projects

When selecting cable hangers for specific projects, several key factors must be considered to ensure safety, efficiency, and longevity. Firstly, the material of the cable hanger plays a crucial role. According to a report by the National Electrical Manufacturers Association (NEMA), steel hangers offer superior strength and durability for heavier installations, while non-metallic options are preferred in environments susceptible to corrosion. Choosing the right material based on the environmental conditions can enhance the lifespan of the installation significantly and reduce maintenance costs.

Another important aspect to contemplate is the load capacity of the cable hangers. The Underwriters Laboratories (UL) stipulates that hangers should be rated for at least 1.5 times the anticipated load. This safety factor is critical, especially in commercial and industrial applications, where the integrity of the cable management system is paramount to operational efficiency. Additionally, project-specific requirements, such as the need for adjustable hangers for future changes in cable layout, should also be assessed to ensure versatility and adaptability in your installation. By meticulously considering these factors, one can select the optimal cable hangers that align with project demands.

Evaluating Weight Capacity and Material Strength of Cable Hangers

When selecting cable hangers for your project, evaluating weight capacity and material strength is crucial. Different projects have varying demands, and the right cable hanger must meet these requirements to ensure safety and reliability. According to a report from the National Association of Electrical Distributors (NAED), cable hangers typically carry loads ranging from 25 to 500 pounds, depending on the material and design. For heavier installations, steel hangers are preferable as they offer greater strength, while plastic options are ideal for lighter applications.

Tips: Always check the manufacturer's specifications for weight capacity before making a purchase. Additionally, consider the environment where the hangers will be used; corrosive settings may require stainless steel or coated hangers to prevent degradation over time.

Material strength is another essential factor. A study by Engineering News-Record (ENR) indicates that hangers made of high-density polyethylene (HDPE) can withstand significant stress, making them suitable for various installations, including outdoor use. When possible, opt for hangers that meet or exceed industry standards, such as those set by the American National Standards Institute (ANSI), to ensure optimal performance and safety.

Installation Methods and Best Practices for Using Cable Hangers

When it comes to installing cable hangers, the right methods can significantly impact the efficiency and safety of your project. First, it’s essential to select the appropriate type of hanger for your specific cables. Options range from clips and hooks to more advanced adjustable systems, depending on the weight and type of cables being supported. Once the right hangers are selected, installation should be performed with precision. Mark the desired locations on the wall or ceiling for optimal cable routing, ensuring that they are evenly spaced to prevent sagging and excessive wear on the cables.

During installation, it’s crucial to use the correct tools and fasteners. Depending on the material of the mounting surface, you may need anchors for drywall or specific screws for concrete. Always ensure that hangers are securely fastened to avoid any accidents or cable damage. For best practices, consider the environmental factors such as temperature fluctuations and humidity, which may affect the integrity of your installation over time. By adhering to thorough installation methods and best practices, you can create a safe, organized, and efficient cable management system that meets your project needs.

How to Choose the Right Cable Hangers for Your Project Needs

| Cable Hanger Type | Load Capacity (lbs) | Installation Method | Best Use Case |

|---|---|---|---|

| J-Hooks | 50 | Screw Mount | General Cable Management |

| Cable Staples | 30 | Nail/Screw | Secure Small Cables |

| Cable Tray | 200 | Suspended Installation | Large Cable Runs |

| Pipe Hangers | 100 | Clamping | Hanging from Pipes |

| Cable Ties | 15 | Self-locking | Temporary Holds |

Common Mistakes to Avoid When Choosing Cable Hangers for Projects

When selecting cable hangers for your project, avoiding common mistakes is crucial for ensuring both safety and efficiency. One frequent error is ignoring load capacity. According to the National Electrical Manufacturers Association, nearly 30% of project delays are attributed to improper hanger specifications, often resulting from overlooking the weight restrictions of the hangers being chosen. Always check the manufacturer's data sheets to confirm that the hangers can support the anticipated load without risk of failure.

Another common misstep is failing to consider the environmental conditions. For example, using standard hangers in environments that experience high humidity or exposure to corrosive elements can lead to premature wear. The International Brotherhood of Electrical Workers suggests that choosing hangers made from corrosion-resistant materials can extend the lifespan of cable installations by up to 40%. Therefore, understanding the specific conditions in which your project will operate is essential for selecting the right type of hanger, ultimately reducing long-term maintenance costs.

Related Posts

-

Discover Premium Cable Racks from China's Leading Manufacturing Hub

-

Exploring Innovative Alternatives to the Best Cable Rack Solutions for Efficient Organization

-

Solutions for Optimal Cable Management with Best Cable Basket

-

Quality Driven Chinese Manufacturing in Global Leader Best Cable Management Tray

-

10 Essential Checklist Items for Sourcing the Perfect Basket Cable Tray for Your Project

-

Ultimate Guide to Efficiently Organizing Cables with Cable Management Trays