How to Choose the Right Cable Tray for Your Electrical Wiring Needs

When it comes to efficient and safe electrical installations, selecting the right cable tray plays a pivotal role in ensuring your wiring meets not only functional requirements but also safety standards. The term "cable tray" refers to a system used to support insulated electrical cables. These trays provide a robust and organized solution for managing cables in commercial, industrial, and even residential settings. With various types of cable trays available, such as ladder trays, perforated trays, and solid-bottom trays, it can be daunting to determine which option aligns best with your specific electrical wiring needs.

In this comprehensive guide, we delve into the critical considerations for choosing the perfect cable tray for your project. Factors such as load capacity, environmental conditions, and the type of cables being used all influence the decision-making process. Whether you're an electrician, a contractor, or a DIY enthusiast, understanding these components is essential for successful electrical installations. As we explore the "2025 Top 10" cable trays, we aim to inform you about the best available options on the market, helping you make an informed choice tailored to your unique wiring requirements.

Understanding Different Types of Cable Trays and Their Applications

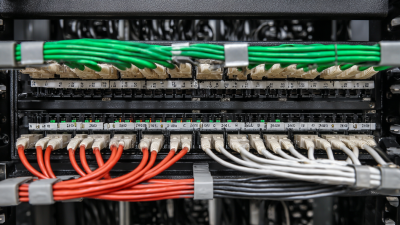

When selecting a cable tray for your electrical wiring needs, it’s essential to understand the various types available and their specific applications. The most common types include ladder, solid bottom, and wire-mesh trays. Ladder trays, recognized for their open design, provide excellent ventilation for cables. They are ideal for large installations and areas prone to heat. Solid bottom trays, on the other hand, offer a more protective environment for cables, making them suitable for indoor use where dust and debris might be an issue.

Tips: When choosing a cable tray, consider the environment where it will be installed. For outdoor applications, opt for UV-resistant materials. Additionally, assess the load capacity needed to ensure it can support the weight of your cables without risk of sagging.

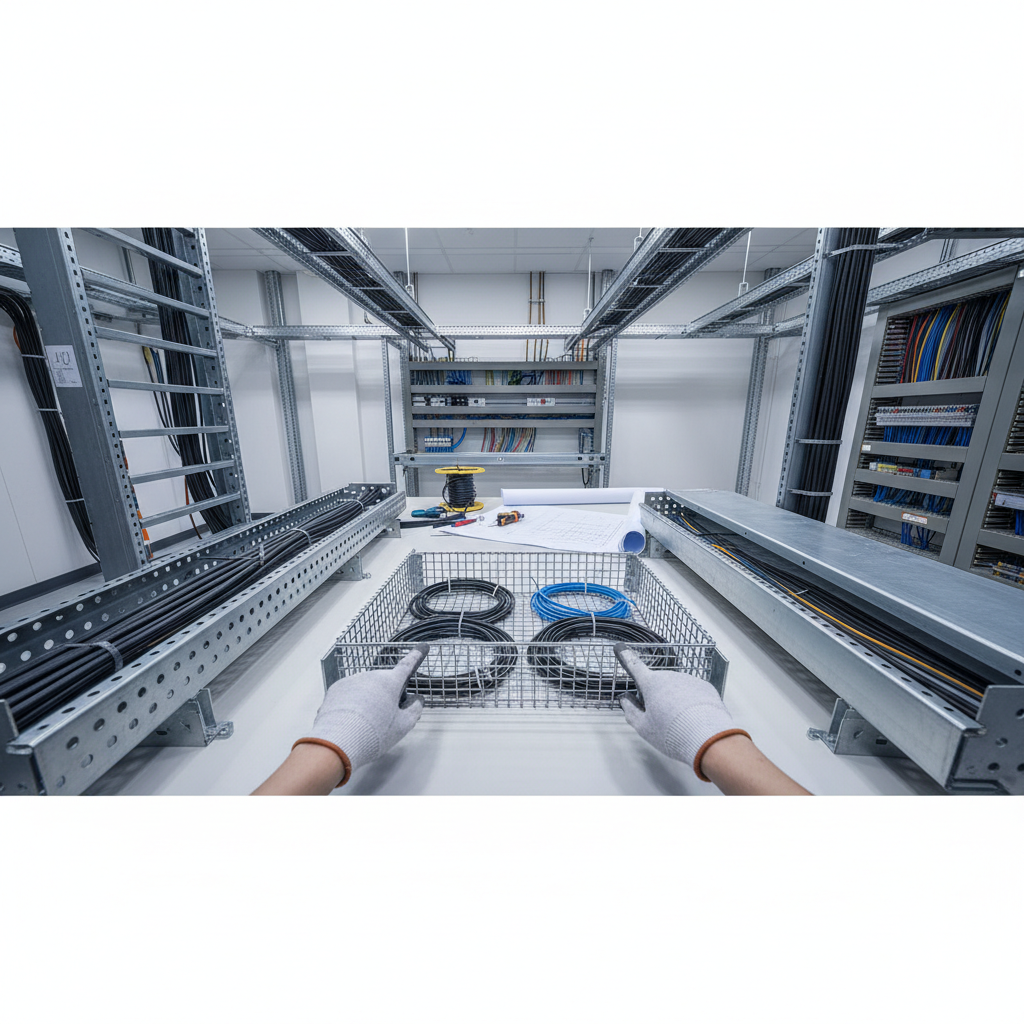

Wire-mesh trays are another popular option, known for their flexibility and ease of installation. They allow for quick access to cables, making maintenance and upgrades simpler. This type is often used in data centers and commercial buildings where cable management is crucial. Be sure to evaluate the spatial constraints of your installation site, as this will influence the choice between these different tray styles.

Key Factors to Consider When Selecting a Cable Tray

When selecting a cable tray for your electrical wiring needs, several key factors must be taken into account to ensure optimal performance and safety. First, the material of the cable tray is crucial; common options include steel, aluminum, and fiberglass, each offering varied resistance to environmental conditions. For instance, steel trays provide robust durability but may require additional coatings for corrosion resistance in harsh environments. In contrast, fiberglass trays are lightweight and non-corrosive, making them suitable for environments where chemical exposure is a concern.

Another factor to consider is the load capacity of the cable tray, which is critical for meeting the specifications of your electrical installation. Given the growing demand for reliable cabling solutions, the global telecommunications cable market is projected to reach approximately $73.71 billion by 2030, with a compound annual growth rate of 7.19% from 2023 to 2030. This growth underscores the importance of selecting cable trays that can accommodate increasing cable volumes and heavier data traffic without compromising structural integrity. Therefore, assessing the intended use, environmental conditions, and regulatory standards will lead to an informed choice that enhances the efficiency and durability of your electrical systems.

Choosing the Right Cable Tray for Your Electrical Wiring Needs

Common Materials Used for Cable Trays and Their Benefits

When selecting a cable tray for electrical wiring, understanding the materials available is crucial in ensuring safety and efficiency. Common materials used for cable trays include steel, aluminum, and fiberglass.

Steel trays are known for their strength and durability, making them ideal for heavy-load applications. They can also be treated for corrosion resistance, which extends their lifespan in harsh environments. The weight of steel, however, may require additional structural support.

Steel trays are known for their strength and durability, making them ideal for heavy-load applications. They can also be treated for corrosion resistance, which extends their lifespan in harsh environments. The weight of steel, however, may require additional structural support.

Aluminum cable trays offer a lightweight alternative to steel, making them easier to install while still providing significant strength. They are naturally resistant to corrosion and are non-magnetic, which is beneficial in environments sensitive to magnetic fields. Additionally, aluminum can be a more cost-effective option for projects where weight is a crucial factor.

Fiberglass is another popular choice, especially in environments prone to moisture and chemicals. Its non-corrosive properties make it suitable for underground installations or areas where exposure to harsh chemicals is common. Fiberglass trays are also lightweight and resistant to a wide range of temperatures, making them versatile for various applications. Each material has unique benefits that cater to specific wiring needs, allowing for informed decisions based on the project requirements.

Installation Guidelines for Optimal Cable Tray Performance

When it comes to installing cable trays for optimal performance in your electrical wiring setup, adhering to industry standards and guidelines is essential. According to the National Electrical Manufacturers Association (NEMA), selecting the right type of cable tray can enhance both system efficiency and safety. For instance, using a properly sized galvanized steel cable tray can improve load capacity while reducing the risk of corrosion, which is critical in humid or corrosive environments.

Tips: Always consider the weight and volume of the cables when choosing a cable tray. As a rule of thumb, allow for at least 25% additional capacity in your tray to accommodate future expansions or replacements. Additionally, ensure that the cable tray is installed at a height that allows for adequate ventilation and avoids overheating, especially in high-density installations.

Proper installation techniques can significantly affect the longevity and reliability of cable trays. For instance, when securing trays, utilize the correct spacing between supports as suggested by NEMA guidelines – typically, every 10 feet for straight runs. Furthermore, ensure that all cable entries are adequately sealed to prevent dust and moisture ingress, which can lead to premature cable failure. Keeping these installation practices in mind will help maintain optimal performance and safety of your electrical systems.

Maintenance Tips to Extend the Life of Your Cable Tray System

When it comes to maintaining your cable tray system, regular inspections are crucial for its longevity. Check for any signs of wear, rust, or corrosion at least twice a year. Pay special attention to joints and seams, where issues are more likely to develop. Cleaning the cable trays regularly can also prevent dirt and debris accumulation, which can lead to deterioration and potential safety hazards.

Another essential tip is to ensure proper cable organization within the trays. Use necessary separators and covers to protect the cables from physical damage and reduce strain on the connections. Overloading a cable tray can lead to premature wear, so always adhere to the manufacturer's load specifications. Additionally, consider using trays made from durable materials that resist environmental factors relevant to your installation location.

Implementing these maintenance practices will significantly extend the life of your cable tray system. Consistent monitoring, cleaning, and organization will help you avoid costly repairs and replacements while ensuring the safety and efficiency of your electrical wiring.

How to Choose the Right Cable Tray for Your Electrical Wiring Needs - Maintenance Tips to Extend the Life of Your Cable Tray System

| Parameter | Value | Notes |

|---|---|---|

| Material | Steel | Durable and strong, suitable for heavy loads. |

| Load Capacity | 500 lbs | Ensure it meets your wiring needs. |

| Width | 12 inches | Ideal for most installation scenarios. |

| Height | 3 inches | Provides enough space for airflow. |

| Coating | Galvanized | Offers corrosion resistance. |

| Maintenance Frequency | Every 6 months | Regular checks increase lifespan. |

| Cleaning Method | Mild soap and water | Avoid harsh chemicals. |

| Inspection Points | Joints, brackets, and cables | Check for wear and tear. |

Related Posts

-

How to Choose the Right Cable Tray for Your Electrical Installation Needs

-

5 Essential Tips for Choosing the Right Wire Cable Tray for Your Project

-

How to Choose the Best Ladder Cable Tray: A Comprehensive Step-by-Step Guide

-

10 Essential Checklist Items for Sourcing the Perfect Basket Cable Tray for Your Project

-

Enhancing Electrical Efficiency: The Advantages of Wire Mesh Cable Trays in Industrial Settings

-

What is a Cable Rack? Understanding Its Importance in Efficient Cable Management