Understanding Wire Basket Cable Trays: The Key to Efficient Cable Management in Modern Infrastructure

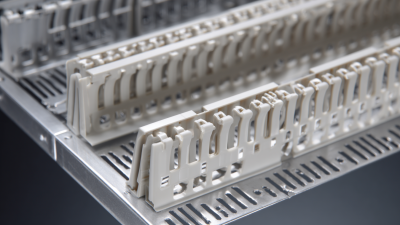

The modern infrastructure landscape is increasingly dependent on efficient cable management solutions to support ever-evolving technological demands. Among various options available, the wire basket cable tray stands out as a versatile and effective choice for organizing and protecting electrical and communication cables. This innovative system simplifies installation and maintenance, while promoting optimal airflow to minimize heat buildup, thereby enhancing the overall longevity of cable systems. As industries navigate the complexities of wiring infrastructures, understanding the principles behind wire basket cable trays becomes essential for ensuring safety, compliance, and operational efficiency. In this guide, we will explore how to effectively utilize wire basket cable trays, highlighting their benefits, installation methods, and best practices that can transform cable management in any setting.

How to Choose the Right Wire Basket Cable Tray for Your Project

When selecting the right wire basket cable tray for your project, it's essential to consider several key factors. First, assess the type and volume of cables that will be routed. This will help determine the size and load capacity of the wire basket required. Make sure to also evaluate the installation environment—outdoor settings may need trays with weather-resistant coatings, while indoor applications could prioritize aesthetics and ease of access.

- Consider future expansions. Choosing a slightly larger tray can accommodate additional cables down the line, saving you from costly modifications later.

- Check for compliance with local codes and regulations. Ensuring that your selected tray meets these standards is crucial for safety and functionality.

Another critical aspect is the material of the wire basket. Galvanized steel and aluminum are popular choices due to their durability and resistance to corrosion. However, if your project involves high temperatures or specific chemical exposure, researching specialized materials can prevent premature failure. Always collaborate with engineers or electrical professionals to ensure that your selection aligns with the broader project requirements.

How to Properly Install Wire Basket Cable Trays for Optimal Performance

Wire basket cable trays are an essential component in modern infrastructure, providing a streamlined approach to cable management. Proper installation of these trays is crucial for ensuring optimal performance and safety in electrical systems. To begin with, selecting the right location for installing the wire baskets is vital. They should be positioned in areas that allow for easy access, maintenance, and sufficient airflow to prevent overheating.

Moreover, ensuring that the trays are securely fastened and level is critical to prevent excessive strain on the cables they carry. It’s advisable to utilize appropriate mounting hardware and spacing guidelines to maintain structural integrity. When routing cables within these trays, avoid overcrowding to allow for proper organization and heat dissipation. By following these installation practices, wire basket cable trays can enhance the efficiency and longevity of cable management systems, ultimately contributing to the seamless operation of infrastructure in an increasingly digital environment.

Understanding Wire Basket Cable Trays: The Key to Efficient Cable Management in Modern Infrastructure

| Dimension | Specification | Material | Load Capacity (lbs) | Installation Height (ft) |

|---|---|---|---|---|

| 6 inches | Wiring Space | Steel | 200 | 10 |

| 12 inches | Wiring Space | Aluminum | 300 | 12 |

| 18 inches | Wiring Space | Galvanized Steel | 500 | 14 |

| 24 inches | Wiring Space | Stainless Steel | 700 | 16 |

How to Integrate Wire Basket Cable Trays into Existing Infrastructure

Wire basket cable trays have become a critical component in modern infrastructure, providing an efficient solution for cable management. As facilities evolve and demand for systematic organization grows, integrating wire basket cable trays into existing infrastructure has become paramount. The recent joint venture in North America reflects the industry's commitment to enhancing cable management solutions, aligning with the anticipated market growth in this sector, which is projected to reach over USD 20.9 billion by 2024, expanding at a robust CAGR of 8.1% from 2025 to 2034.

For effective integration, it's essential to assess the existing layout and identify key areas where wire basket cable trays can streamline cable organization. Begin by mapping out the current cable paths and determining points of congestion. Installing wire basket trays in these areas can significantly reduce clutter and improve accessibility.

Tips:

- Ensure that the selected wire basket trays comply with local standards and regulations for safety and fire prevention.

- Regularly inspect the trays after installation to ensure all cables are secured and that there are no hindrances to airflow, which is crucial for maintaining optimal cable performance.

How to Maintain and Inspect Wire Basket Cable Trays for Longevity

Wire basket cable trays are a fundamental component of modern cable management systems, offering both flexibility and efficiency. To ensure their longevity and performance, regular maintenance and inspection are crucial. According to a report by the National Electrical Manufacturers Association (NEMA), proper cable management can reduce system downtime by up to 30%, emphasizing the importance of routine checks. Inspecting wire basket cable trays for signs of wear, corrosion, or mechanical damage helps prevent potential hazards and ensures compliance with safety standards.

To maintain these trays, it is recommended to conduct inspections at least bi-annually. During these checks, assess the integrity of the tray, ensuring that cables are securely fastened and not subject to crushing or abrasion. Furthermore, cleaning the trays regularly can prevent dust and debris buildup, which can cause overheating issues. The International Electrotechnical Commission (IEC) also suggests that maintaining the proper cable spacing in trays not only optimizes airflow but also enhances the overall efficiency of electrical systems, mitigating risks of electrical faults and extending the lifespan of the cables housed within.

How to Maximize Space Efficiency with Wire Basket Cable Trays in Design

Wire basket cable trays have emerged as a pivotal solution for efficient cable management in modern infrastructure. As the global cable tray market is projected to grow significantly—valued at approximately USD 4.2 billion in 2023 and expected to expand at a compound annual growth rate (CAGR) of over 6.8% through 2032—it's clear that the demand for effective cable organization systems is on the rise. This trend underscores the importance of utilizing wire basket trays, which maximize space utilization and simplify maintenance.

To maximize space efficiency in design, consider the following tips: first, evaluate the layout of your existing infrastructure and identify areas where wire basket trays can integrate seamlessly without obstructing airflow or access. Second, leverage vertical space by installing trays above workstations or along walls, allowing for easier cable management while freeing up vital floor space. Lastly, ensure clear labeling of cables within the trays to facilitate quick identification and troubleshooting, which will save time and reduce downtime during maintenance processes.

The projected growth of the single rail cable tray market—from USD 87.64 million in 2025 to USD 142.48 million by 2032—highlights the increasing recognition of organized cable systems. By adopting wire basket cable trays, businesses and facilities can not only enhance operational efficiency but also contribute to a more streamlined and modern workspace.

Related Posts

-

7 Essential Tips for Choosing the Right Wire Basket Cable Tray for Your Business Needs

-

7 Reasons Why Black Cable Tray is the Ultimate Solution for Your Wiring Needs

-

Uncompromising Quality in Best Tray Cables Made in China for the Global Market

-

7 Essential Tips for Maximizing Efficiency with Wire Basket Trays

-

Discover Premium Cable Racks from China's Leading Manufacturing Hub

-

How to Select the Right Plastic Cable Tray for Your Electrical Installation Needs